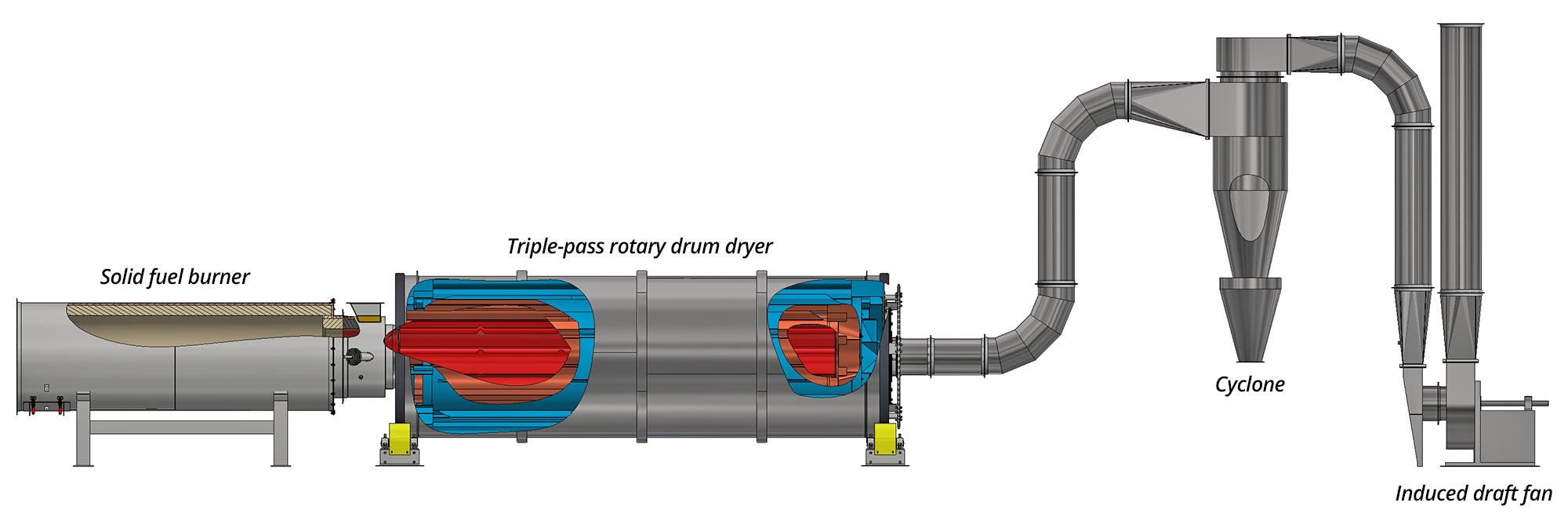

Wet material enter the inner cylinder, propelled through the system via a hot gas air stream. The material is continuously lifted by the cylinder flights and showered through the concurrent stream of hot gases. The three full-length interlocked concentric cylinders rotate together design for the highest velocity in the inner-pass. As lighter particles quickly lose 60% of their moisture and move out of the cylinder, heavier/denser particles are retained until they also lose 60% of their moisture.